Concrete Batching Plant Controllers

Showing all 6 results

Automatic Control System for Concrete Batching Plant

Efficiency, consistency, and automation drive modern construction—and that’s exactly what an automatic concrete batching plant control system delivers

At Samyak, we deliver solutions from a concrete batching plant control panel for small setups to a concrete batch mix plant with computer control for large-scale projects—ensuring consistent quality and smooth operation.

Our solutions are built for every plant type—from simple computer-controlled setups to fully automated systems managing complex mixes and large-scale production.

Why Use a Concrete Batch Plant Control System?

A concrete batch plant control system is the brain of your plant.

It manages every step of the mixing process—from weighing raw materials and adjusting water ratios to coordinating mix timing.

Whether for a small operation or large-scale commercial production, our system delivers:

- Accurate recipe management

- Automated material weighing and blending

- Real-time monitoring and reporting

- Intelligent fault detection with alarms

- Centralised computer-based control

By automating your batching process, you reduce human error, ensure consistent quality, and achieve peak plant efficiency.

Our Latest Models of Automatic Control Systems

Explore Samyak’s advanced range of batching plant controllers, designed for precision, reliability, and ease of operation.

Batch Controller SMIT 1523

A versatile and high-performance batch controller engineered for precise material proportioning and automated plant operation.

Reverse Mixture Plant controller SMIT 1301L (Three BIN Weight Indicator)

Provides accurate control of three-bin material weighing with intuitive operation and durable performance.

Reverse Mixture Plant controller SMIT 1301 (Three BIN Weight Indicator)

Compact and efficient controller for managing three-bin reverse mixture plants with reliable batching accuracy.

Reverse Mixture Plant Weight Indicator SMIT 1519 (Single BIN Weight Indicator)

Designed for single-bin applications, offering accurate weight measurement and smooth batching control.

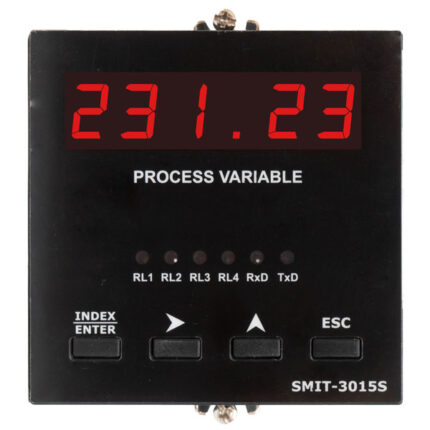

Reverse Mixture Plant Weight Indicator SMIT 3015S (Single BIN Weight Indicator)

Robust single-bin indicator that ensures precise load measurement and dependable plant operation.

Water Dispenser SMIT 1272

Automated water dispensing system delivering accurate dosing and improved control over water-cement ratio in concrete production.

Key Features of Samyak Concrete Batch Plant Controls

Our concrete batch plant controls are engineered with today's construction industry in mind. Key features are:

Automated Batching Sequence

Our concrete batching plant control panel ensures accurate material proportioning and consistent mix quality, batch after batch, without manual effort.

Real-Time Monitoring

Track every batch live with detailed logs and analytics, enabling proactive quality checks and operational insights.

User-Friendly Interface

Operate via intuitive touchscreen or computer-based HMIs designed for easy navigation and reduced operator training time.

Multiple Recipe Management

Save, manage, and quickly switch between mix designs—ideal for a concrete batch mix plant with computer control handling diverse project needs.

Load Cell Integration

Achieve highly accurate weighing of cement, aggregates, water, and additives for improved quality control.

Data Logging & Reports

Access complete batch histories, material consumption records, and production reports for analysis and compliance.

Safety Interlocks & Alarms

Integrated safeguards prevent incorrect batching, alert operators of issues, and ensure safe plant operation.

Advantages of a Computerised Concrete Batch Mix Plant

A computer-controlled concrete batch mix plant provides a variety of benefits over manual systems:

Increased Accuracy

Eliminates human errors in weighing and batching, ensuring precise material proportions every time.

Enhanced Productivity

Automates batching and shortens cycle times, enabling faster, more consistent production output.

Standardized Quality

Maintains uniform mix quality by accurately controlling ingredient ratios across all batches.

Labor Efficiency

Reduces the need for constant manual supervision, allowing staff to focus on higher-value tasks.

Data Analysis

Provides access to real-time and historical production data for performance tracking and process optimisation.

Applications and Integration of Concrete Batch Plant

The Samyak automatic control system for concrete batching plants is ideal for a wide range of applications, including:

- Ready-mix concrete plants

- Large-scale infrastructure projects

- Precast concrete production

- Road and Bridge Construction

- Hydropower and dam works

Our systems can also be seamlessly integrated with ERP platforms, remote dashboards, and cloud-based monitoring to create a complete digital ecosystem for concrete production.

Why Samyak for Concrete Plant Automation?

Samyak is a renowned industrial automation and process control company providing:

Three Decades of Industry Experience

With 30+ years in automation and process control, Samyak brings unmatched expertise to every project.

In-House R&D and Manufacturing

Our dedicated research, design, and production teams ensure innovation, quality, and faster delivery.

Customised Solutions for All Plant Sizes

From compact setups to large-scale operations, we tailor systems to match your exact requirements.

End-to-End Assistance

We support you through every stage—installation, training, service, and long-term maintenance.

Competitive Pricing with Unparalleled Reliability

Get cost-effective solutions without compromising system performance or durability.

Contact us today for a demo or consultation and experience smarter, safer, and more efficient concrete production.

FAQs – Automatic Control System for Concrete Batching Plant

What is an automatic control system for a concrete batching plant?

It is the central unit that manages weighing, mixing, sequencing, and discharge through PLCs, ensuring accuracy and consistency.

How does Samyak’s batching plant control system improve efficiency?

By automating recipes, weighing, water dosing, and timing, Samyak ensures faster cycles, reduced errors, and uniform concrete quality.

What are the key features of Samyak’s control panels?

Automated batching, real-time monitoring, touchscreen HMIs, multiple recipes, load-cell accuracy, data logs, and safety alarms.

How do load cells improve batching accuracy?

They ensure precise weighing of cement, aggregates, water, and additives—reducing waste and maintaining mix quality.

How does automation save costs in batching?

By reducing material waste, preventing operator errors, and enabling real-time corrections, cutting operational costs.

How do advanced control systems prevent errors and maintain quality consistency?

These systems monitor operations in real time, detect deviations, and can adapt to raw material or environment variations to ensure consistent mix quality.